In massive processing amenities, these components are sometimes received into storage silos or tanks without a clear designation of (or break between) lots. These storage amenities could additionally be emptied and cleaned infrequently, making it unimaginable to prove if or when a contaminant had been used and when it was not current within the tank or silo. Correct labelling is very essential when the product incorporates a number of allergens. The producer will need to have allergen management methods in place to assure that allergens are excluded from products in which they need to be absent. Therefore, the producer must have sturdy techniques to assure that the correct components are utilized in its formulations, and that labels are correct and properly applied.

An extra advantage arising from necessities tracing of this type, is that it facilitates the search for inconsistencies (for example, inconsistencies occurring between the different stage requirements) and allows simpler identification of potential gaps. We might, for example, notice that a certain larger degree requirement (e.g., business requirement) does not have any associated decrease degree necessities. This may signal that the requirement was not decomposed accurately and might need been skipped. Traceability will catch these issues early on, offering provide chain visibility in what you manufacture for customers and businesses.

These articles and associated content material is the property of The Sage Group plc or its contractors or its licensors (“Sage”). Please don’t copy, reproduce, modify, distribute or disburse with out categorical consent from Sage. These articles and associated content is supplied as a common guidance for informational functions solely. These articles and associated content material isn’t a substitute for the guidance of a lawyer (and particularly for questions associated to GDPR), tax, or compliance professional. When doubtful, please consult your lawyer tax, or compliance skilled for counsel.

There are a selection of commercially obtainable software techniques designed to assist food producers in documenting the identity of materials as they flow by way of the method of receiving, storage, production and distribution. They have the further benefit of helping the producer within the manufacturing of identity preserved products such as natural, non-GMO and kosher merchandise. Some of these systems are very complex and the preliminary implementation is normally a daunting task. This article discusses issues and options concerning traceability for Systems Engineering projects.

In the UK, the most typical cause of food recalls in 2014 was microbiological contamination, at 24% (that includes E. coli at 10%, Salmonella at 4% and Listeria at 3%). In the EU from January through August 2015, 14% of meals alerts were attributable to allergens and 37% were due to pathogenic microorganisms (which consists of Salmonella at 19%, Listeria at 9% and E. coli at 4%). In the U.S. between eight September 2012 and seven September 2015, the most typical cause of meals remembers was undeclared allergens, which accounted for forty three.6% of all remembers. The next most typical purpose for a recall was contamination with Salmonella at 28.7%, followed by contamination with Listeria monocytogenes at 17.3%. We would additionally wish to thank the reviewers that helped to enhance the paper and Moni for her nice support. Section 5 applies the classification to a selection of present approaches and hereby illustrates the state-of-the-art in traceability.

It will hold your small business compliant, but it might also drive increased worth out of your technology investments. 1) Information from producers, suppliers, and distributors is effectively recorded. It’s all about strengthening themselves in opposition to weak spots within the provide chain uncovered by the pandemic, not to point out environmental adjustments, trade tensions, regulation, and beyond. Naturally, the relation between a given requirement and different artifacts isn’t the one relation which will occur. There are additionally relations between specific artifacts, like for instance, between design and the code which implements it or between the code and the check procedure which is there to verify its correctness.

Be A Part Of Sage

It is how you because the project supervisor make the most of this device that is going to ultimately impression your organization’s improved product design, growth, and deliverability. Learning more about requirement traceability is step one in path of making certain that your end merchandise are designed to the requirements of the product proprietor and that there’s accountability all through the process of product evolution. Project scheduling is a occupation that’s at its greatest when the scheduler understands the most effective scheduling practices recognized by many professional organizations. A good project schedule is a dynamic tool to help plan and execute the project and to forecast completion dates. If the assumptions change the dates are likely to change as a outcome of the scheduler has represented the plan faithfully in logic and durations, avoiding using lags and leads, constraints and incomplete logic resulting in dangling activities. The results of the schedule may be discovered within the high quality of the critical or longest path, whole float that represents realistically the flexibility of the schedule and statusing of present schedules that is full.

The hierarchy itself, along with creating links between larger level requirements and their decrease level counterparts permit to hint the way in which how the higher degree ones have been decomposed. Whatever the manufacturing vertical, traceability can be the necessary thing to defending each the consumer and your reputation within the occasion of a product recall. The standards around product security and quality have never been higher—any doubts surrounding your products might very nicely have a long-lasting effect on your model worth.

Model Traceability

The manufacturer can create a stronger record of the packaging utilized by saving a bodily pattern of the label or by taking an image of the label or package deal used. Its goal is to support attribute recombination to new analysis options and to overcome present issues with naming conventions. The utility of the schema is shown at the example of two novel approaches from Fraunhofer IPK and Daimler AG which https://www.globalcloudteam.com/ are specializing in issues in trace link recording inside Systems Engineering projects. The implementation, analysis and functional comparison for both approaches are introduced based on an exemplary automotive system. First results present a big reduction of required trace recording efforts and good acceptance from engineers within the automotive business.

A new report from IDC says that 96% of process producers shall be shifting their focus to growing visibility, with 57% drilling down into the end-to-end supply chain particularly. The U.S. Food and Drug Agency has identified eight main allergens, Canada has identified 11 and the European Union has recognized 14 foods and chemicals that fall beneath its allergen labelling necessities. It is incumbent on the food producer to comply with the labelling requirements within the country the place the product is to be sold.

Top Project Management Software

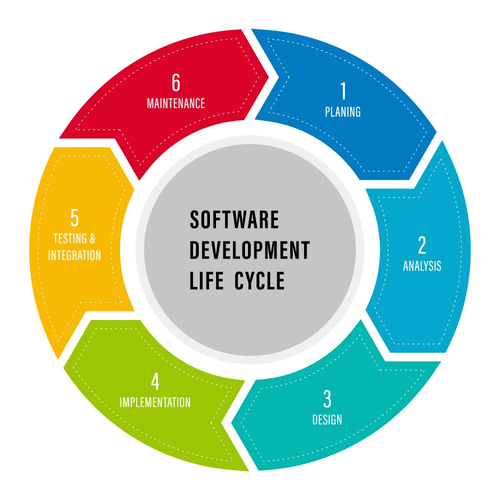

Traceability describes relationships between two or extra parts all through the event process. In software development, it identifies and paperwork the derivation of these merchandise from the set hierarchy and defines the required elements to determine whether each individual product continues to be necessary. In project administration, requirement traceability outlines the relationship between customer necessities through a Requirement Traceability Matrix. In conclusion, not solely is traceability required by regulatory businesses and third-party audit requirements what is vertical traceability, but it is a key component of risk management and the management of meals safety and high quality. Having a strong, documented system to make sure traceability assists companies in meeting regulatory or certification requirements for food safety and helps to shortly determine and recall affected merchandise within the occasion of contamination. Vertical traceability demonstrates the consistency of dates, standing, and scope requirements between completely different levels of a schedule—summary, intermediate, and detailed.

It could additionally happen when a manufacturer changes an ingredient provider and fails to notice that the ingredient doesn’t comprise the identical sub-ingredients as the ingredient it replaced. In addition, incorrect labelling could occur if a worker chosen the wrong label, container or packaging material for a product, or if the producer is informed by its supplier that the ingredient it delivered was mislabelled. An organization is also going to want to develop the correct workstation processes and metrics.

Companies, growing mechatronic products, want to provide clients with progressive and highly effective options. One of the challenges these firms face right now, is to handle the increasing complexity1 of products which intensifies with every added perform. Embedding and integrating functionalities from completely different disciplines is a major supply of innovation [2] and an important factor in today’s market competition but in addition drives system complexity and therefore complexity inside system improvement. Further features with comparable impression are the discount of hardware prototypes and the rising diploma of modularisation. Coping with missing hardware prototypes requires extra refined, holistic system simulations that often depend on fashions or data that could be extensive unfold throughout the company, suppliers or customers.

Vertical traceability identifies the origin of things and follows these identical gadgets as they journey by way of the hierarchy of the work breakdown structure to the project teams and ultimately to the customer. Software for established businesses in search of larger effectivity, flexibility, and insight. We advocate that you just strategy your future with a significant dedication to digital and automatic traceability.

- Traceability is about monitoring and tracing your supply chain—identifying all relevant knowledge for the raw supplies used to produce and distribute finished merchandise to their ultimate vacation spot.

- However, the “basic” version of tracing the requirements could also be carried out even when maintaining our requirements as simple textual content recordsdata.

- First, it’s traceability which is the key sauce to superior provide chain visibility.

- It is a risk-management tool that also permits meals business operators or authorities to withdraw or recall merchandise which have been recognized as unsafe.

- Food firms and distribution techniques are becoming increasingly bigger, more consolidated and globalised and supply chains are increasingly complicated.

To help, listed beneath are takeaways when excited about supply chain visibility for your small business. Are you planning to introduce a project administration software resolution to your employee? To help you make the right selection, we’ve gathered one of the best project administration internet functions. Horizontal traceability is not required to statisfy bidirectional traceability.It identifies the realatinships among related gadgets across work teams or product parts for the purpose of avoiding potential conflicts. ERP permits you to obtain a whole product history as and when you should, from ingredients used to finished items, considering multi-site, multi-company, and multi-legislative product journeys. Download this IDC report again to learn why automating traceability is important now greater than ever.

Traceability ensures you could show all stakeholders that you are a viable, trustworthy provider and might provide the depth of knowledge customers and regulatory enforcement agencies require. Another issue that has increased recollects is the improved capabilities of well being investigators and epidemiologists to correctly attribute pathogens to a single source. National or regional information sharing systems (such as PulseNet) enable investigators to accurately match pulse subject gel electrophoresis patterns and entire genome sequencing knowledge. With this data, investigators can decide if a pathogen found to be the source of a foodborne sickness in one space matches pathogens found in different sicknesses in different areas. Other information techniques for sharing and monitoring foodborne illness embody the Rapid Alert System for Food and Feed within the EU and the Food Alert System within the UK. By conducting food historical past interviews with the affected folks, investigators can establish frequent food sources, finally identifying a single supply or ingredient liable for the outbreak.

Process producers have been keeping inventory records manually for years, but this prevents them from reaching the required flexibility and efficiency that provides them an edge over the competitors in their business. Tracking is concerning the progression of merchandise from one sequence to the following and the way they transfer by way of the manufacturing course of. Through information, you can see where merchandise are, who’s labored on them, and the way lengthy until they’re completed.